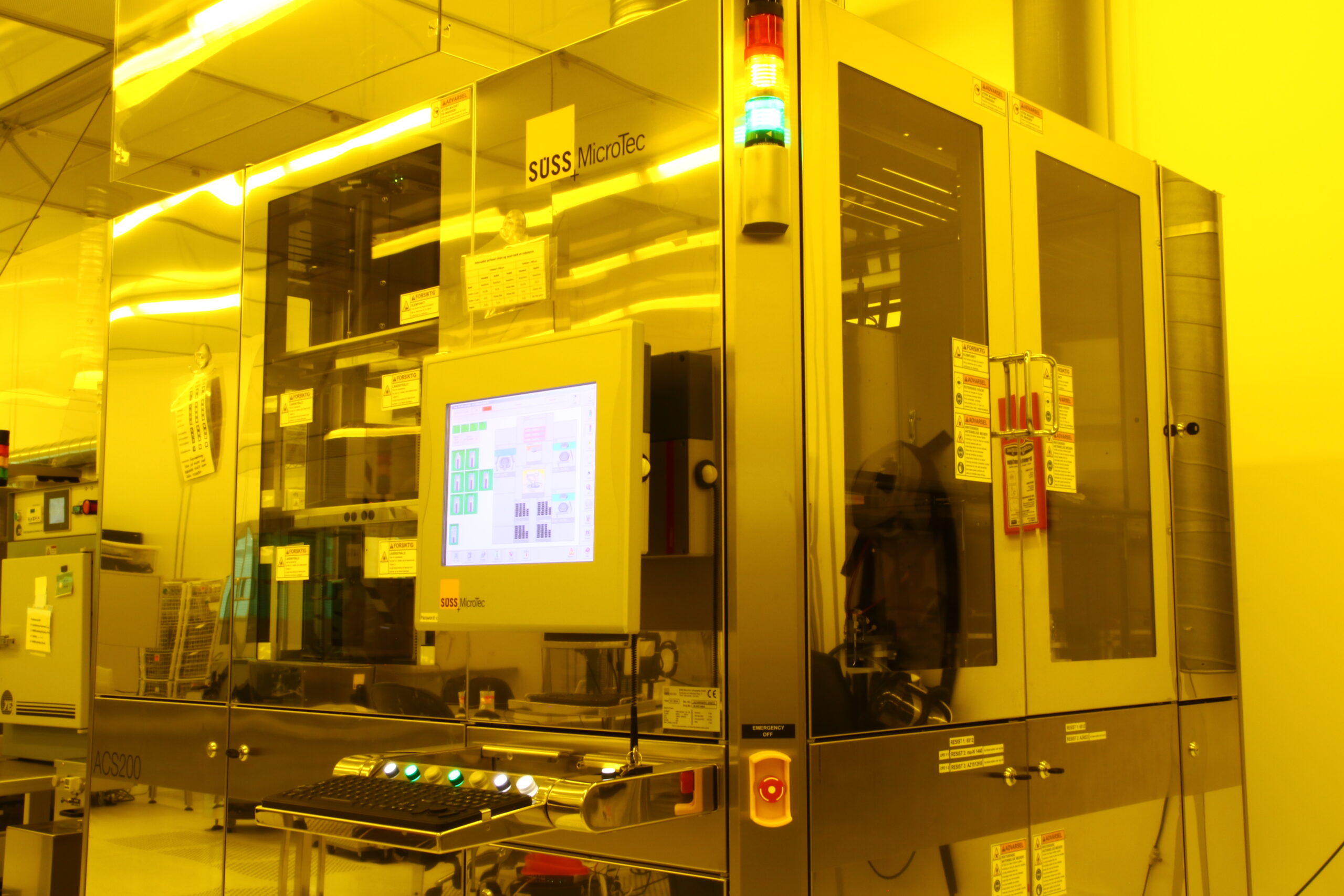

Suss Automated Spin coating & Puddle development

Wafer size: 150 mm

The Suss MicroTec – ACS200 Gen3 tool has two spin coating modules, three hot plates and a puddle development module. Different resists can be spin coated. There are two cassette loading stations for fully automated cassette-to-cassette wafer handling. All modules have edge handling, making it suitable for double-sided applications.

Spin coating is the process of evenly coating a spinning substrate with a photosensitive resist. The resist is normally dispensed at the center of the wafer. Subsequent acceleration as well as the rotation speed and the time allotted to the individual steps ensure that a homogeneous layer thickness remains after excess resist is spun off. Alongside the process parameters, the physical properties of the solution or photoresist determine the thickness of the applied film. Spin coating is limited in use to structures without too high topography.

Puddle developing involves dispensing a defined quantity of developer to the exposed substrate, gently spinning it to spread the developer. Due to the surface tension of the developing agent, a convex puddle is formed on the wafer. Once developing time is completed, the wafer is rotated quickly to spin off the developer agent. The wafer is subsequently rinsed with deionized water and dried, once again at a high rotation speed. The main advantage of the technique is that only very little developing agent is required while maintaining excellent process results.

NTNU NanoLab

NTNU NanoLab UiO MiNaLab

UiO MiNaLab USN MST-Lab

USN MST-Lab SINTEF MiNaLab

SINTEF MiNaLab