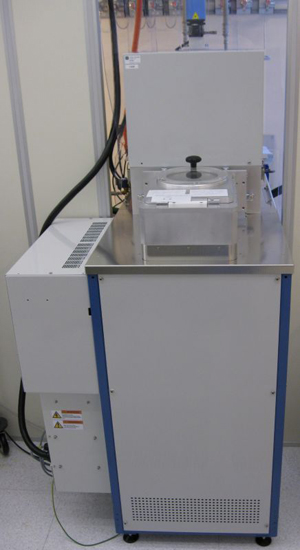

ICP-RIE Cryo

Model: PlasmaLab System 100-ICP180

Manufacturer: Oxford Instruments

Area: Thin Film & Dry Etch

Inductively Coupled Plasma etching is an anisotropic dry-etching process where material is removed with the use of chemically reactive plasma under a low pressure (~1-100 mTorr). Typically the material removed is a thinfilm previously deposited on a wafer. The ICP-RIE uses two independent RF sources, one to strike plasma in a gas mixture and one to create a DC bias which extracts and accelerates ions and radicals from the plasma towards a sample surface. This gives indipendent control of ion density and energy. ICP RIE is a popular dry-etching technique because of its possibilty for high ecth rates, great selectivity and reduced ion bombardment.

- Materials allowed: everything which is not considered as contaminating within NanoLab rules, sample size can’t exceed 101.7 mm (4”) in diameter and 5 mm in thickness.

- Process gases: H2, O2, N2, Ar, CF4, SF6, CHF3, He, CH4, Cl2 and BCl3.

- Two 13.56MHz RF sources

- Operating temperature: -150°C to 400°C

- Typical applications: Low damage etching of III-V species, high rate anisotropic etch of Si for MEMS applications, high rate SiO2 etching, sputter etching applications (Pt, Al, etc.).

- Base Pressure: 5E-7 Torr

NTNU NanoLab

NTNU NanoLab UiO MiNaLab

UiO MiNaLab USN MST-Lab

USN MST-Lab SINTEF MiNaLab

SINTEF MiNaLab