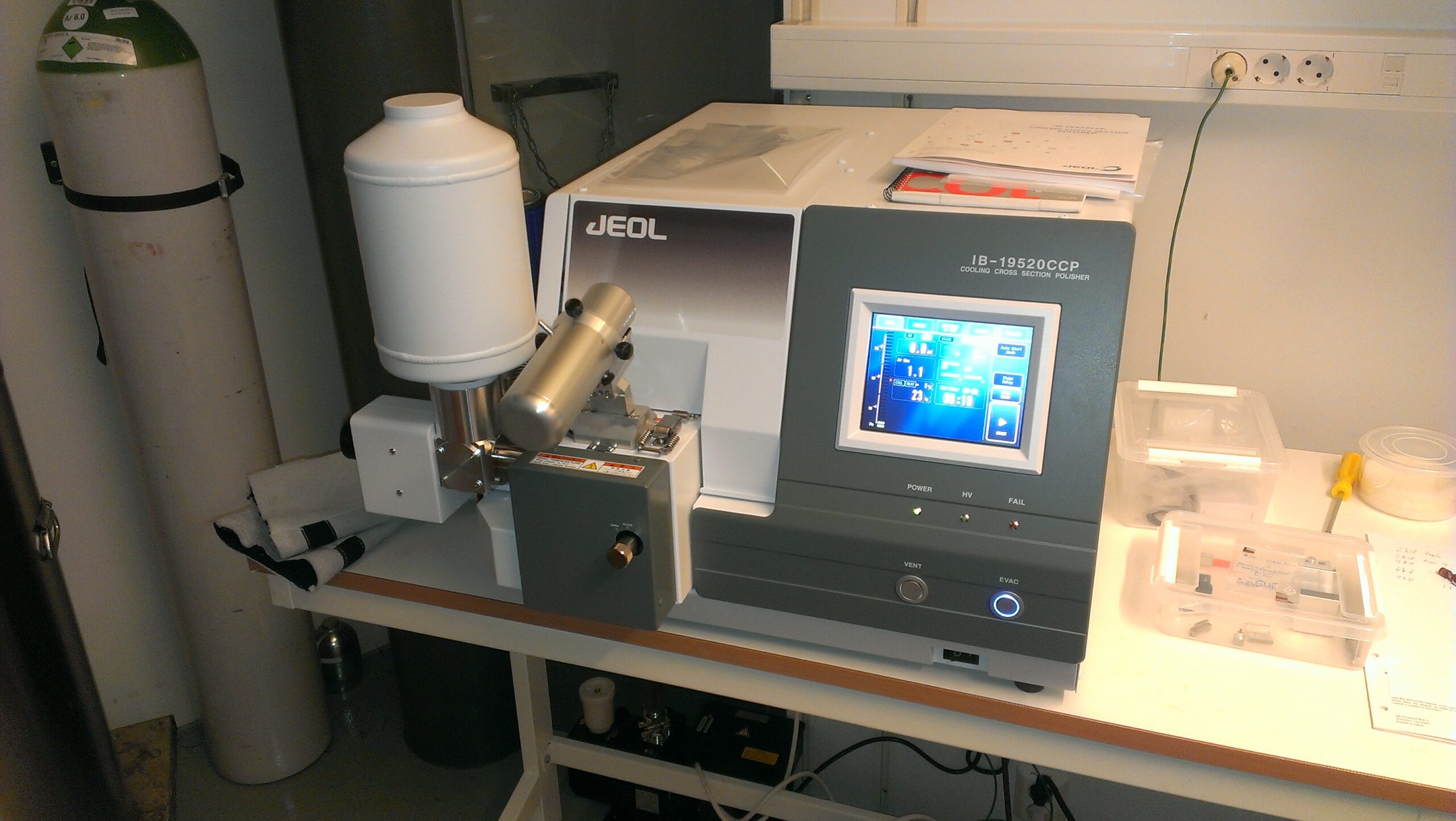

Cross Section Polisher

Model: IB-19520CCP

Manufacturer: Jeol

Area: MiNaLab Corridor O2.1A

|

Instrument model: |

JEOL IB-19520CCP Cross Section Polisher. |

|

Technology Description: |

The instrument is suitable for the preparation of pristine cross-sections of a specimen for analytical scanning electron microscopy (SEM-EDS), electron probe microanalysis (EPMA), or scanning probe microscopy (SPM). Cross-sections of layered materials, metals, ceramics, porous materials or even plastics and paper can be prepared with little roughness over a wide area (larger than 500μm). Thermal damage of heat-sensitive materials (e.g., low melting point metals and composite materials) can be reduced by cooling the specimen with liquid nitrogen during processing. A transfer vessel allows vacuum transfer of the polished sample to our JEOL IT-300 SEM without exposure to air. |

|

Technical Information: |

Accelerating voltage: 2 – 8 kV. Ion beam width: 500 μm (FWHM). Milling speed: 500 μm/h (at accelerating voltage 8kV; Specimen Si; 100 μm from edge). Sample size: Maximum specimen size of 11 mm (W) x 8 mm (L) x 3 mm (T). Specimen holder ultimate cooling temperature: – 120 oC or less. Specimen cooling hold time: 8 h or more. Air isolation system: transfer vessel. |

|

|

NTNU NanoLab

NTNU NanoLab UiO MiNaLab

UiO MiNaLab USN MST-Lab

USN MST-Lab SINTEF MiNaLab

SINTEF MiNaLab